Thyristor Power Controlled Battery Charger

Price 50000.0 INR/ Piece

MOQ : 1 Piece

Thyristor Power Controlled Battery Charger Specification

- Product Type

- Thyristor Power Controlled Battery Charger

- Material

- Mild Steel / Powder Coated Steel Cabinet

- Power

- Up to 1000 Amps (customizable) Ampere (amp)

- Frequency (MHz)

- 50 / 60 Hz Hertz (HZ)

- Working Temperature

- 0C to 50C Celsius (oC)

- Speed Regulation Method

- Thyristor Controlled

- Dimension (L*W*H)

- Custom Sizes Available (e.g., 750mm x 600mm x 1800mm) Millimeter (mm)

- Weight

- Approx. 75-250 kg (depends on rating) Kilograms (kg)

- Color

- Grey / Blue

Thyristor Power Controlled Battery Charger Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces, Piece Per Day

- Delivery Time

- 2 Days

About Thyristor Power Controlled Battery Charger

Our company counted among the most prominent trader and supplier of Thyristor Controlled Battery Charger in India. These are made at our vendor's advanced manufacturing unit using optimum quality raw and latest machinery in synchronization with defined industrial norms. These are available to our valuable customer at a market reasonable price. This Thyristor Controlled Battery Charger is made by using iron material which makes it corrosion resistant. These are well known for its durability.Advanced Control and Safety

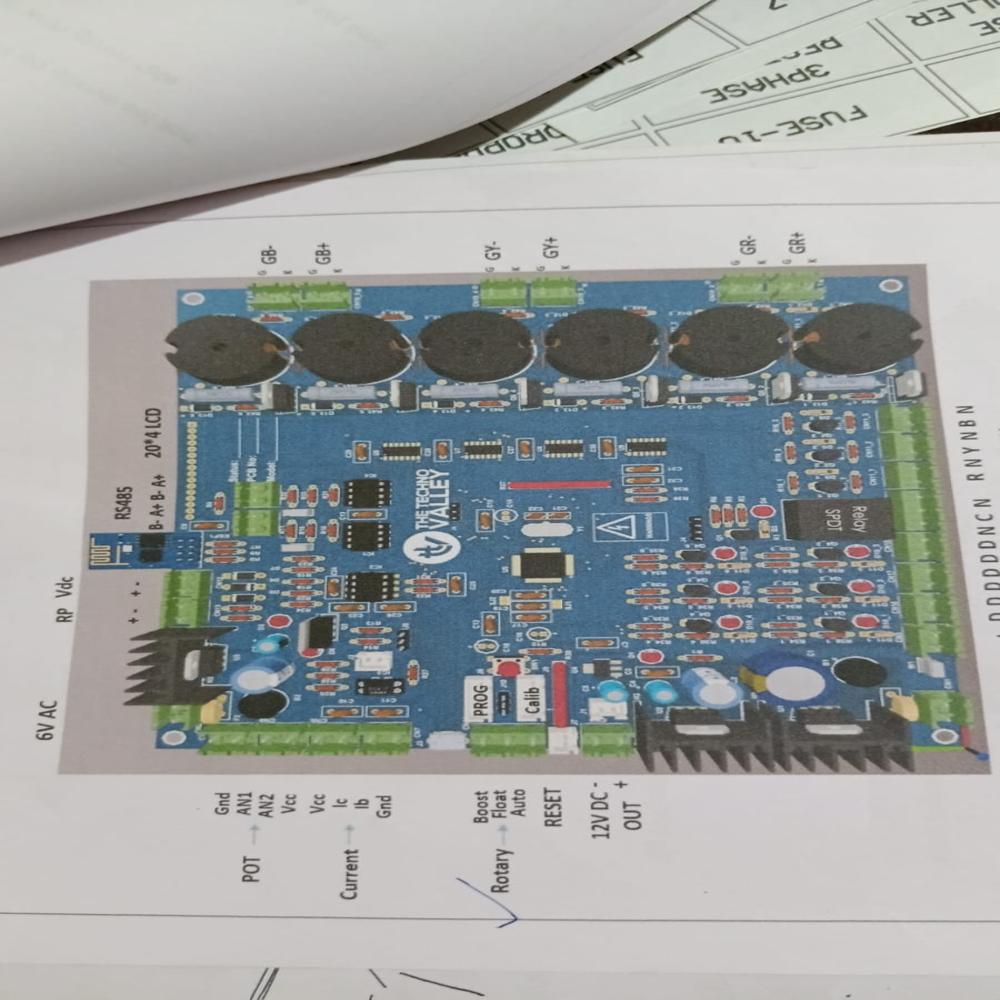

This charger uses a sophisticated Thyristor Controlled system, ensuring precise regulation of charging current and voltage. Catering to various battery specifications, the charger includes overload, short circuit, reverse polarity, and high/low input protection. Visual monitoring is enabled via digital volt/amp meters and LED indicators, enhancing safety and operational convenience.

Flexible Design and Customization

Crafted for versatile installations, the unit is available in floor or panel-mounted options, with customizable dimensions and colors. Whether deployed in substations or power plants, the charger adapts to your space requirements. Both natural air and forced air cooling systems are available to suit higher ratings and environmental conditions.

FAQs of Thyristor Power Controlled Battery Charger:

Q: How does the Thyristor Controlled Battery Charger benefit industrial applications?

A: Its thyristor-controlled system ensures precise and reliable battery charging, accommodating high currents up to 1000A and multiple DC voltages. This guarantees safe operation, reduced maintenance, and compatibility with a wide spectrum of industrial batteries.Q: What safety protections are included in the charger?

A: The charger features comprehensive safety protections such as overload, short circuit, reverse polarity, and high/low input voltage safeguards. These systems help minimize downtime, equipment damage, and ensure secure operation under various conditions.Q: When should forced air cooling be selected over natural cooling?

A: Forced air cooling is recommended for higher rating chargers, usually when charging currents approach the upper end (above 400A), or when the charger operates in environments with elevated ambient temperatures or restricted airflow.Q: Where can this battery charger be installed?

A: This charger is versatile in its mounting options, offering both floor and panel installation. It is suitable for deployment in control rooms, industrial environments, substations, power plants, and telecom or railway facilities.Q: What is the process for customizing the chargers features and dimensions?

A: Customization is based on the customers order, specifying required output voltage, charging current, cabinet size and color. Manufacturers, distributors, and suppliers across India can adjust these parameters to match specific operational needs.Q: How are digital volt/amp meters and LED indications useful during charger operation?

A: Digital volt/amp meters provide real-time data on charging status, improving monitoring accuracy. LED indications offer clear, immediate visual signals on charger operation and fault conditions, enabling quick response and troubleshooting.Q: What advantages does compliance with IS/IEC standards provide?

A: Compliance ensures the charger meets established safety, performance, and quality benchmarks. This not only enhances reliability but also facilitates regulatory approval for use in diverse industrial sectors.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Thyristor Controlled Battery Charger Category

Float Cum Boost Charger

Price 1000000 INR / Piece

Minimum Order Quantity : 1 Piece

Rated Frequency : 50 Hertz (HZ)

Input Voltage : 220V AC 1Ph. .+/ 20% & 415V AC 2Ph./3Ph.+/ 10% Volt (V)

Output Voltage : DC 12V, 24V, 48V, 110V, 220V etc. +/ 1% Volt (V)

Usage : Battery

"We are dealing in North India Only."

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS